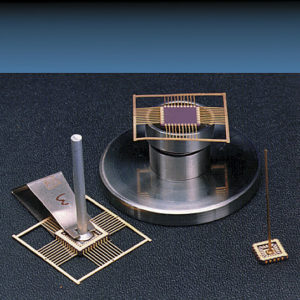

Using the Romulus Workstation and the Pull Down Breaking Point Platform, stud pull tests result in a quantitative measure of the coating’s or die’s adhesion/adherence. The Stud Pull Die Bond Strength test is performed by bonding the pre-epoxy coated face of a nail shaped stud to the sample surface, and then applying an exact perpendicular controlled rate of force until sample failure. Our 70 MPa (10,000 psi) epoxy bonds to virtually any solid, is low stressing if a small stud is used, and goes from enamel-like to water consistency just prior to polymerizing. This optimizes exact perpendicular stud mounts. A special high strength epoxy is used for large area bonding such as die bond or SMT tests. Lower cure temperature epoxy is available.

Stud Pull Die Bond Strength

This Module supports Die-Bond, SMD and other bonded component tests according to Mil Std. 883, method 2027. This will require certain facilities and supplies not included with the basic Romulus.